Contenu de la page de détails du produit

Oil seal is a common sealing device that plays a very important role in mechanical systems. Simply put, it is a mechanical component used to seal lubricating oil. Lubricants perform critical functions in mechanical transmission systems, lubricating, cooling and protecting moving parts to ensure efficient operation of mechanical equipment. However, lubricating oil may not be able to do its job if it leaks or becomes contaminated from the outside world, which is where oil seals come in.

The role of lubricants in mechanical systems cannot be underestimated. It lubricates frictional parts, reducing friction and wear, thereby prolonging the life of mechanical equipment. In addition, lubricants absorb and dissipate heat, keeping components from overheating while protecting against oxidation and corrosion. However, lubricating oil needs to be tightly sealed during its working process to avoid leakage or contamination.

Axle seals are essential components in the automotive industry, especially in vehicles with solid rear axles. These safe High -pressure oil seals play a vital role in preventing oil spills and protecting the internal components of the axle from dust, dirt and other contaminants.

- Premièrement, le joint d'huile est un composant de précision, ce qui affecte les performances de l'utilisation d'un assemblage et d'une garde inappropriés. Faites attention au joint d'huile lors du transport et du stockage :

- N'ouvrez pas l'emballage d'origine, faites attention si l'emballage est endommagé, essayez de conserver l'huile dans l'emballage d'origine avant le montage ;

- Évitez la lumière directe du soleil, ne placez pas à proximité de sources de chaleur à haute température, car cela favorisera le vieillissement du caoutchouc;

- Le joint d'huile ne doit pas être dispersé à volonté. Faites attention à la poussière et au sol pour vous assurer que le joint d'huile est fermé ou recouvert ;

- Lors du transport et de l'utilisation du joint d'huile, afin d'éviter la déformation du joint d'huile et la chute du ressort, veuillez ne pas donner trop d'impact ;

- Le joint d'huile ne peut pas être attaché avec une corde fine et il ne doit pas être suspendu au clou ou à la ligne métallique, ce qui endommagerait la lèvre d'étanchéité.

- Ne pas sceller l'huile dans un endroit humide, ce qui ferait rouiller les pièces métalliques ;

- Ne placez pas les pièces d'étanchéité près de la télévision et produisant de l'ozone ;

- Veuillez ne pas frotter les extrémités de vos lèvres avec vos ongles ou des objets durs pour éviter d'endommager les lèvres d'étanchéité ;

Deuxièmement, l'assemblage du joint d'huile, quelle que soit l'adéquation de la conception de l'installation du joint d'huile et du choix du joint d'huile, si l'assemblage est grossier, il ne peut pas jouer pleinement la fonction de la réservation du joint d'huile.

- When the oil seal is installed, the outer surface should be applied to an appropriate lubricant. The mouth of the lip should be applied to the suitable clean lubricant, and the oil seal with dust -proof lips should be filled with the suitable clean lubricant between the main lips.

- Tournez les extrémités de la lèvre du joint d'huile vers le côté du fluide d'étanchéité. Ne montez pas l'inverse.

- Lorsque le joint d'huile est entré dans le siège, l'outil dédié doit être enfoncé pour empêcher la position de s'enfoncer.

- Les filetages, liaisons, fleurs, etc. du sort de la lèvre du joint d'huile doivent être adoptés pour éviter d'endommager la lèvre et l'assembler avec un outil dédié.

- Placez les trous du siège horizontalement et appuyez uniformément. Ne pas incliner pour l'avancement obligatoire.

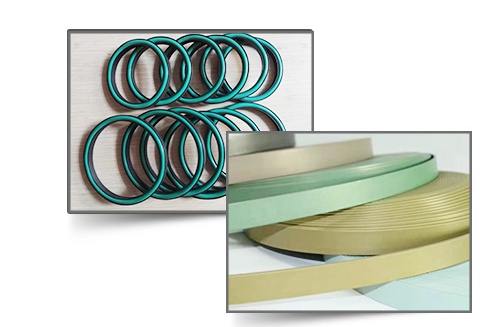

Materials used:

Usually consists of a flexible sealing lip made of a high performance elastomeric material such as nitrile rubber, fluorocarbon or silicone. The sealing lip is responsible for contact with the rotating surface to provide a tight seal. The metal housing is usually made of steel or other durable material that can withstand high temperatures and pressures. Metal housings can also be coated or plated for added corrosion resistance.

Design Features:

A variety of design features are available to provide a reliable and effective seal. The flexible seal lip is designed to conform to the shape of the rotating surface to provide a tight seal. Metal housings can also include additional features such as dust lips or auxiliary seal lips to provide additional contaminant protection and improve sealing performance. Shaft oil seal designs can also be customized to fit specific vehicle applications, such as those found in cars, trucks or heavy equipment.

Performance Specifications:

Oil seals are designed to withstand temperatures from -40°C to 200°C or higher, depending on the specific application. They can withstand pressures of up to 10,000 PSI or higher, depending on the application. The seal lips are designed to provide low friction operation and long service life even at high temperatures. Axle oil seals are also designed to resist chemical and oil degradation, ensuring long-lasting performance.

Installation and Maintenance:

Axle oil seals should be installed using proper tools and techniques to ensure proper installation and sealing. Improper installation can result in premature seal failure, which can lead to axle damage and failure. Regular maintenance is recommended to inspect seals for wear or damage and replace as needed. Proper lubrication is also important to ensure proper operation and prevent premature seal failure. It is important to use the recommended lubricant and follow the manufacturer’s installation and maintenance recommendations to avoid premature seal failure and axle damage.

Product Details

Shaft oil seals, also known as grease seals or shaft seals, are made of high-quality materials such as rubber, silicone or polyurethane. The safe High -pressure oil seal is designed to fit tightly around the half shaft and create a barrier between the inside and outside of the axle housing. The seal is held in place by a metal retainer that is screwed or clamped to the axle housing.

Axle safe High -pressure oil seals are available in various sizes and designs to suit different types of axles and vehicles. The most common designs are single-lip and double-lip seals. Single-lip seals have one sealing lip, while double-lip seals have two sealing lips for additional protection against oil leakage.

How the product works

The working principle of the axle safe High -pressure oil seal is relatively simple. As the axle spins, oil splashes around inside the axle housing. Oil needs to be contained within the housing and prevented from leaking. This is where shaft oil seals come in.

The sealing lip is in continuous contact with the rotating shaft, creating a tight seal between the shaft and housing. The seal also has a spring that helps maintain contact between the seal and the shaft. Spring tension keeps the seal lip in contact with the shaft, even as the shaft rotates and vibrates.

The outside diameter of the seal is held in place by a metal retainer attached to the shaft housing. This prevents the seal from rotating with the shaft and ensures that the seal lip remains in contact with the shaft at all times.

safe High -pressure oil seal product application

Safety china oil seal design axle oil seals are used in various vehicles including cars, trucks, SUVs and commercial vehicles. They are an important part of the solid rear axle assembly commonly found in trucks and SUVs. These seals are also used in live axle assemblies, which are common in performance cars and race cars.

The shaft oil seal is usually located on the outside of the shaft housing, near the shaft end. They are installed during assembly and need to be replaced if damaged or worn. Signs of damaged or worn seals include oil leaks, unusual noise from the axle, and excessive vibration.

All in all, the axle safe High -pressure oil seal is a vital component in the automotive industry, which plays a vital role in preventing oil leakage and protecting the inner parts of the axle. KNT as an oil seal supplier for durable oil seal customization is available in various designs and sizes, so it is imperative to choose the right seal for your vehicle and ensure it is installed correctly. Regular maintenance and inspection of these seals can help avoid costly repairs and keep your vehicle running smoothly.