Product details page content

Product name

type

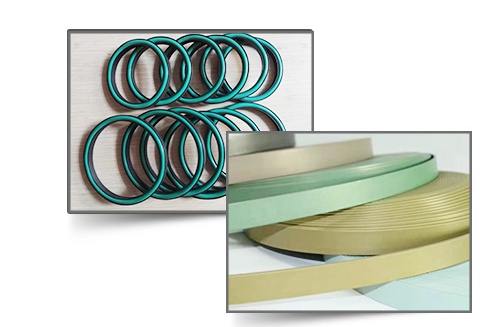

Sealing ring

Material

Metal shell+NBR rubber

effect

Dust -proof

brand

ENO

model

DKB type; GA type; iron shell dust -proof sealing ring

Sample or spot

Spot goods

Whether to

Standard Parts

Operating temperature

-30-150 (℃)

use pressure

4-40 (MPA)

The main role of dust -proof sealing circle is to remove the dirt such as the dust, gray sand, rain and frost attached to the outer surface of the outer surface of the cylinder, and prevent external dust and rain from entering the sealing mechanism.

The dust -proof sealing ring is divided into various types and sizes, with polycolic and outsourcing iron shells. Therefore, the range of use and targeting objects is more extensive.

Advantages: special abrasion resistance, squeeze, impact resistance, small compression deformation, wide adaptation range, easy installation

KNT is an innovative high -tech enterprise. It is engaged in the design, production, sales and services of sealing parts. Continue to improve the competitiveness of customers ‘products. At the same time, in order to ensure the requirements of customers’ continuous improvement of performance, Shanding has carried out continuous and long -term research and development investment in the areas of new materials, seal elements and sealing systems.

The main products of KNT are: excellent china high temperature oil seal, skeleton oil seal, rubber miscellaneous parts, O-ring, V-clip, disk seal, etc., and can also customize products according to customer requirements. The sealing products produced by Shanding are widely used in household appliances, hydraulic pressure, construction machinery, automobiles and other industries.

The dustproof sealing ring is a key component in the mechanical system, and its main function is to protect the outer surface of the cylinder and the sealing mechanism connected to it. Its function is not limited to removing dirt, dust, rain, frost and other dirt attached to the outer surface of the cylinder, but also prevents these pollutants from the external environment from entering the sealing mechanism to ensure the normal operation of the mechanical system.

Remove dirt from external surfaces

Air cylinders are often used to push or pull mechanical parts whose outer surfaces are exposed to a variety of harsh environments. During operation, the outer surface of the cylinder will become unclean due to the adhesion of dust, dust, rain, frost and other dirt. These dirt may not only damage the outer surface of the cylinder, but also affect its operating efficiency. One of the main functions of the dust seal is to remove these dirt regularly to ensure that the surface of the cylinder remains clean and smooth, thereby maintaining the performance and life of the cylinder.

Prevent contaminants from entering the sealing mechanism

Sealing mechanisms are very important in mechanical systems, they are responsible for keeping liquids or gases inside the system and preventing the entry of impurities from the external environment. If contaminants enter the sealing mechanism, they can damage the sealing elements, leading to leaks and reduced system performance. Another key function of the dust seal is to act as a barrier, preventing outside dust, rain and other contaminants from entering the sealing mechanism, thereby maintaining its effectiveness.

Materials and design

Dust seals are usually made of wear and corrosion resistant materials such as rubber, silicone or polyurethane. These materials have good elasticity and durability, and can effectively remove dirt and prevent pollutants from entering in different working environments. In addition, the design of the seal ring usually takes into account the requirement of tightly fitting the outer surface of the cylinder to ensure effective sealing and reliability.

Application field

Dust seals are widely used in various mechanical and industrial fields, including hydraulic systems, pneumatic systems, automobiles, construction machinery, agricultural equipment, etc. Whether it is a small air cylinder or a large hydraulic cylinder, the dust seal is a key component to ensure that the outer surface of the cylinder is clean and protect the reliable operation of the sealing mechanism.

In short, dust seals are the guardians of the mechanical system. They maintain the performance and reliability of the mechanical system by removing dirt from the outer surface and preventing pollutants from entering the sealing mechanism. These small but critical components play an important role in ensuring the proper functioning and longevity of mechanical systems.

Build a technical research and development team with rich experience in the world, and the forward -looking product design concept provides customers with a tailor -made sealing solution

Promote sensitive manufacturing methods, continue to improve quality, efficiency and other aspects, and form industry advantages in mold manufacturing, vulcanization, edge and assembly, etc.

The research results of the new material development team have obtained large -scale promotion and application in industrial fields such as high -speed, high pressure, low friction, and vibration reduction in these years.

The inner diameter of the oil seal and the shaft contact surface is well sealed to prevent the oil from leaking through the inner diameter

Multi -lip design blocks external pollution

High -temperature oil seal | Combination oil seal | Mud water seal | Low friction oil | Bridge oil seal

One -stop purchase of a comprehensive seal solution for customers tailor -made products for customers

Oil seal, skeleton oil seal, rubber seal, fluorine rubber oil seal, automobile oil seal, small appliance oil seal, combined oil seal, high -speed oil seal, car bridge oil seal and other products

Type: sealing ring

Material: Polyethypening

Function: sealing of the shaft