Product details page content

Product name

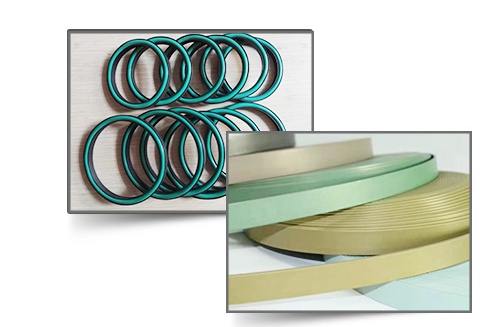

KNT is your reliable automobile shock absorber oil seal manufacturer, products also include engine crankshaft oil seals, valve stem oil seals, axle oil seals, transmission oil seals, gas spring oil seals, air conditioner compressor oil seals, construction machinery seal products and other rubber parts .

Oil seal is the habit of general seals. Simply put, it is the sealing of lubricating oil. It is a mechanical element that is used to seal oil (oil is the most common liquid matter in the transmission system, and also refers to the meaning of general liquid matter). It isolates the components that need to be lubricated in the transmission part from the contribution parts, so as not to let the lubrication lubricate Oil leakage. The static seal and dynamic seal (generally reciprocating) use the sealing part to be called oil seal.

|

Oil seal |

h |

h1 |

h2 |

h4 |

D1 |

D3 |

D4 |

D4Placeθ |

Structure type |

|

11-31-9.5 |

3 |

3.3 |

3.3 |

2.7 |

17.5 |

27 |

21.3 |

30° |

Plate formal dressing gas lip single spring |

|

12.4-32-9.5 |

3.8 |

3.7 |

3.3 |

3.4 |

19 |

28.3 |

22.7 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-33.3-9.5 |

3.8 |

3.8 |

3.5 |

3.3 |

19.5 |

27 |

25 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-33.8-2.8/9.8 |

2.8 |

3 |

2.9 |

3.6 |

19 |

29.7 |

23.6 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-33-7.8 |

3.7 |

3.6 |

1.3 |

3.5 |

19 |

26.5 |

25.3 |

10° |

Plate formal dressing gas lip single spring |

|

12.4-35.5-3.6/9 |

3.6 |

4 |

2.6 |

3.9 |

19 |

33 |

24.4 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-36-8.8 |

3.6 |

4 |

2.4 |

3.5 |

19 |

30 |

21.5 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-36-8.8N |

3.6 |

4 |

2.4 |

3.5 |

19 |

30 |

21.5 |

0° |

Plate formal dressing gas lip single spring |

|

12.4-38.8-9.5 |

3.55 |

4.3 |

2.8 |

1.8 |

19 |

34.8 |

25.4 |

61° |

Board format, sealing lip double spring |

|

12.4-38.8-9.5N |

3.55 |

4.3 |

2.8 |

1.8 |

19 |

34.8 |

25.4 |

61° |

Board format, sealing lip double spring |

|

12.5-32-3.3/9.5 |

3.3 |

4.1 |

3 |

3.5 |

19 |

27.5 |

22.6 |

0° |

Plate formal dressing gas lip single spring |

|

12.5-32-3.6/9.7 |

3.6 |

4.2 |

2.9 |

2.4 |

19 |

28 |

23 |

50° |

Board format, sealing lip double spring |

|

12.5-36-9.5 |

3.5 |

3.8 |

2.85 |

3.2 |

19 |

31.5 |

23.5 |

0° |

Plate formal dressing gas lip single spring |

|

12.5-36.5-10.4 |

4.1 |

4.2 |

3.2 |

3.9 |

19 |

31 |

26 |

38° |

Board format, sealing lip double spring |

|

12.5-42.4-3/10 |

3 |

4 |

3 |

1.8 |

19 |

34 |

19.5 |

50° |

Board format, sealing lip double spring |

|

14-36.3-10 |

4.2 |

3.1 |

3.3 |

3.8 |

20.5 |

32.4 |

23.2 |

0° |

Plate formal dressing gas lip single spring |

|

15.8-36.8-1.5 |

3 |

4 |

3.8 |

4 |

22 |

34.5 |

26.6 |

47° |

Plate formal dressing gas lip single spring |

|

15-35.5-9 |

3.5 |

3.8 |

3.3 |

2.3 |

22 |

33 |

27.2 |

47° |

Plate formal dressing gas lip single spring |

|

15-36-3.2/8.8 |

4 |

4.2 |

2 |

4.2 |

22 |

32 |

25.8 |

0° |

Plate formal dressing gas lip single spring |

|

16-42.4-3/10 |

3 |

4 |

3 |

2.5 |

22.5 |

34 |

23.2 |

45° |

Plate formal dressing gas lip single spring |

|

17-36-4.4/9.5 |

4.4 |

4 |

2.6 |

2.6 |

23.5 |

32 |

27.3 |

18° |

Plate formal dressing gas lip single spring |

|

18-40-9.7 |

3.6 |

3.8 |

3.2 |

3.9 |

24.5 |

37.5 |

30.7 |

42° |

Plate formal dressing gas lip single spring |

|

18-40-10 |

3.6 |

4 |

3.5 |

4 |

24.5 |

36.5 |

30.8 |

47° |

Plate formal dressing gas lip single spring |

|

18-42-9.5 |

3.6 |

4.3 |

2.6 |

3.6 |

24.5 |

37 |

29.8 |

0° |

Plate formal dressing gas lip single spring |

|

18-44.8-8.8 |

3.6 |

3 |

2.6 |

3.7 |

24.5 |

40 |

31.6 |

47° |

Plate formal dressing gas lip single spring |

|

18-45-8.8 |

3.6 |

3.7 |

2.6 |

3.7 |

24.5 |

40.4 |

31.6 |

47° |

Plate formal dressing gas lip single spring |

|

18-46-8.8 |

3.6 |

3.8 |

2.6 |

3.8 |

24.5 |

40.4 |

31.7 |

47° |

Plate formal dressing gas lip single spring |

|

18-49-8.8 |

3.6 |

3.7 |

2.6 |

3.7 |

24.5 |

44.4 |

31.6 |

47° |

Plate formal dressing gas lip single spring |

|

18-53-8.8 |

3.6 |

3.7 |

2.6 |

3.7 |

24.5 |

48.4 |

31.6 |

47° |

Plate formal dressing gas lip single spring |

|

20-40.5-3.7/10.7 |

3.7 |

5.4 |

2.2 |

3.8 |

26.5 |

36 |

0 |

0° |

Plate formal dressing gas lip single spring |

|

20-40-3.55/9 |

3.6 |

4.3 |

2.5 |

3.6 |

26.5 |

35.7 |

30.3 |

14° |

Plate formal dressing gas lip single spring |

|

20-50.2-8.3 |

3.7 |

3.8 |

2.1 |

3.9 |

26.5 |

44.4 |

33.6 |

47° |

Plate formal dressing gas lip single spring |

|

22-39-8.7 |

3 |

4.2 |

2.2 |

2.5 |

29 |

35 |

31.2 |

10° |

Board format, sealing lip double spring |

|

22-40.8-9 |

3.1 |

3.8 |

3.2 |

2.8 |

29 |

38.3 |

31.4 |

35° |

Plate formal dressing gas lip single spring |

|

22-40-10.4 |

3.7 |

3.8 |

3.5 |

2.5 |

28.5 |

36.2 |

30.6 |

7° |

Board format, sealing lip double spring |

|

22-41-9.2 |

3.55 |

3.7 |

3 |

2.6 |

28.5 |

37.2 |

33.4 |

18° |

Board format, sealing lip double spring |

|

22-42.2-8.8 |

3.6 |

3.7 |

2.6 |

3.7 |

28.5 |

38.2 |

33.8 |

47° |

Plate formal dressing gas lip single spring |

|

25-45-10 |

3.5 |

4 |

3.5 |

4 |

32 |

41 |

36 |

0° |

Board format, sealing lip double spring |

|

28-49-9 |

3.7 |

3.9 |

2.3 |

3.6 |

36.8 |

43 |

38.4 |

5° |

Plate formal dressing gas lip single spring |

In mechanical engineering, oil seal is a common and indispensable sealing device. It undertakes the key task of sealing lubricating oil. In short, oil seals are used to seal mechanical components in liquids. This covers the most common liquid substances in transmission systems and also applies to the sealing needs of various liquid substances. The main function of the oil seal is to isolate the mechanical parts that need lubrication from the external environment to prevent lubricating oil from leaking.

Static and dynamic seals

Oil seals can generally be divided into two main types: static seals and dynamic seals. Both seal types play key roles in different machinery applications.

- Static Seals: Static seals are used on relatively stationary mechanical parts where no significant mechanical movement is involved. They are designed to ensure that lubricant oil does not leak from the mechanical system while blocking the entry of external impurities and contaminants. Static seals usually use elastic materials such as rubber to ensure reliable sealing.

- Dynamic Seals: Dynamic seals are used where lubricant is required to pass through mechanical parts, which often involve reciprocating or rotating motion. The design of dynamic seals needs to be more complex to ensure that sealing performance is maintained even under high-speed rotation or frequent movement. These seals often include additional structures, such as springs or sealing tips, to accommodate the requirements of the moving parts.

Application areas

Oil seals play a key role in a variety of mechanical systems and industrial applications. Here are some common application areas:

- Automobile industry: In automobile engines, oil seals are used to seal crankshafts, camshafts and other rotating parts to ensure the circulation of engine oil and the lubrication of mechanical parts.

- Industrial equipment: Oil seals are used in various industrial equipment such as pumps, compressors, fans and hydraulic systems to ensure their sealing performance and stable operation.

- Agricultural machinery: Agricultural equipment, such as tractors and harvesters, also use oil seals to maintain lubrication and sealing performance in various agricultural environments.

In general, the oil seal is an indispensable guardian of mechanical lubrication. They protect mechanical equipment from the threat of leakage and contamination by effectively sealing lubricating oil, ensuring continuous and efficient operation of equipment, extending life and reducing maintenance costs. They are indispensable components in the modern engineering field.