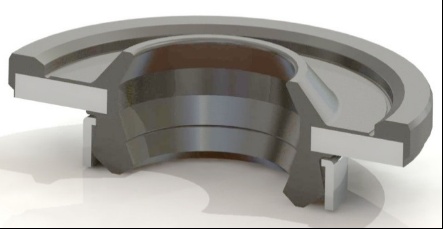

Oil seals play a vital role in numerous industrial and automotive applications, serving as a vital barrier against the accidental leakage of lubricating oil and other fluids. These seals present considerable challenges, especially in high temperature environments where they must withstand extreme temperatures and harsh conditions. To meet these stringent requirements, the market has witnessed China becoming an important supplier of high temperature oil seals, offering a wide selection of materials and products to meet the diverse needs of various industries.

KNT high temperature oil seals are designed to maintain their function and integrity even at extreme high temperatures. They are commonly used in engines, turbines, compressors and other machinery where temperatures can reach high levels. The ability to withstand these extreme conditions is critical to preventing oil spills, maintaining peak performance and extending the life of critical components.

KNT’s position as a leading supplier of high temperature oil seals stems from its remarkable advancements in material science and manufacturing capabilities. Chinese KNT manufacturers invest heavily in R&D to develop specialty materials with excellent resistance to heat, abrasion and chemical exposure. These materials typically include advanced elastomers such as fluoroelastomers (FKM), perfluoroelastomers (FFKM), and high-temperature silicone rubbers, which offer excellent thermal stability and elasticity.

In addition to offering a wide range of materials, Chinese KNT suppliers also focus on product innovation and customization. They understand the diverse needs of various industries and work closely with customers to develop tailor-made solutions. Whether it is a specific temperature range, chemical compatibility or pressure resistance, there is an oil seal that meets the precise needs of different applications.

Learn about high temperature oil seals

popular china high temperature oil seal is used in applications where the temperature exceeds 120°C. These seals must be able to withstand high temperatures, pressure and aggressive chemicals while maintaining their sealing properties. Such applications include automotive engines, industrial machinery, power plants, and oil and gas exploration.

High temperature oil seals are usually made of materials such as silicone, fluororubber (FKM), perfluororubber (FFKM) and polytetrafluoroethylene (PTFE). These materials have unique properties that allow them to withstand high temperatures, chemical exposure and other challenging conditions.

material selection

Selecting the proper material for high temperature oil seals is critical to ensuring optimum performance and service life. Several factors must be considered when selecting materials, including temperature, pressure, chemical exposure and friction.

- Silicone: Silicone is a popular high-temperature oil seal material known for its excellent heat resistance, low compression set, and good chemical resistance. However, it is less resistant to hydrocarbons, solvents and fuels.

- FKM: FKM is a fluoroelastomer with excellent heat resistance, chemical resistance and compression set resistance. It is ideal for high temperature applications where harsh chemicals are present.

- FFKM: FFKM is a perfluoroelastomer with excellent chemical resistance, high temperature performance and low compression set. It is commonly used in oil and gas exploration, chemical processing and semiconductor manufacturing.

- PTFE: PTFE is a synthetic polymer with excellent chemical resistance, low friction and high temperature performance. It is commonly used in applications requiring a high level of chemical resistance.

application notes

When selecting a popular china high temperature oil seal material, specific application requirements must be considered. Sealing materials must be compatible with the fluid being sealed, the temperature and pressure conditions, and the type of equipment being used.

In high temperature environments, thermal expansion must also be considered. If the seal material has a different coefficient of thermal expansion than the mating surface, leaks and premature seal failure will result.

Advancement of high temperature oil seal technology

With the increasing demand for high temperature oil seals, Excellent china oil seal design has made significant progress in sealing technology. Leading domestic manufacturers continue to develop new materials and products to meet the needs of various industries.

An example of Chinese innovation is the development of graphene-based materials for high-temperature oil seals. Graphene has excellent thermal, chemical resistance, and mechanical strength, making it a promising material for high-temperature applications.

Benefits of using Chinese high temperature oil seals

Popular china high temperature oil seal has several advantages over its competitors. These benefits include:

- Cost-effective: China is known for its cost-effective manufacturing capabilities, allowing customers to purchase high-quality seals at competitive prices.

- Wide variety of materials: China offers a wide variety of high-temperature oil seal materials, including silicone, fluororubber, perfluororubber, PTFE, and graphene-based materials.

- Customization: Chinese manufacturers can customize seals to meet specific application requirements, providing customers with tailor-made solutions.

- Quality Control: Chinese manufacturers have instituted strict quality control measures to ensure their products meet international standards.

Common applications of high temperature oil seals in China

China high temperature oil seals are widely used in all walks of life. Some common applications include:

- Car Engine: High temperature oil seals are used in the engine to prevent oil leakage and ensure optimal performance.

- Industrial Machinery: Oil seals are used in various industrial machinery applications including pumps, compressors and hydraulic systems.

- Power Plant: High temperature oil seals are used in turbines, generators and other power plant equipment to prevent fluid leakage.

- Oil and Gas Exploration: Oil seals are used in drilling equipment, pipelines and valves to prevent fluid leakage and ensure safe and reliable operation.

Best Practices for Using Chinese High Temperature Oil Seals

To maximize the performance and service life of high temperature oil seals, manufacturers must follow best practices when selecting and using seals. These practices include:

- Proper Installation: Seals must be installed correctly to ensure proper sealing and prevent premature failure.

- Regular maintenance: Regular maintenance and inspections help to identify and solve problems before they lead to failure.

- Compatibility: Seals must be compatible with the fluid being sealed, the temperature and pressure conditions, and the type of equipment being used.

- Storage: Seals should be stored in a clean, dry and cool environment to prevent damage or degradation.

- Replacement: Seals should be replaced periodically as recommended by the manufacturer.

in conclusion

KNT has become a leading china high temperature oil seal supplier, offering a wide range of materials and products to meet the needs of various industries. Selecting the correct material and following best practices can help manufacturers maximize the performance and service life of high temperature oil seals. With continuous advancements in sealing technology, China is expected to remain at the forefront of innovation in high temperature oil seals, providing customers with customized solutions to meet their specific needs.

Related Products